Recently,Shenzhen HIKING PV Technology Co., Ltd.(Hereinafter referred to as:HIKING PV)The first phase of the 2.5MWp distributed photovoltaic power generation project carried out in Guangzhou – the factory building reinforcement project – has been completed. The power station project is constructed under the EPC general contracting model of “design – procurement – construction”. After the power station is completed, it is expected to generate 2.5 million kilowatt-hours of electricity annually, save 850 tons of standard coal consumption, and reduce carbon dioxide emissions by approximately 2,043 tons.

PV power stations have significant advantages such as sustainability, ecological environmental protection and economic benefits, and are one of the most superior green energy sources. Specifically, the energy-saving and protective effect brought by each square meter of photovoltaic system is equivalent to that of 100 square meters of afforestation. Therefore, developing renewable energy projects such as photovoltaic power generation will become one of the most effective ways to solve environmental problems such as smog and acid rain.

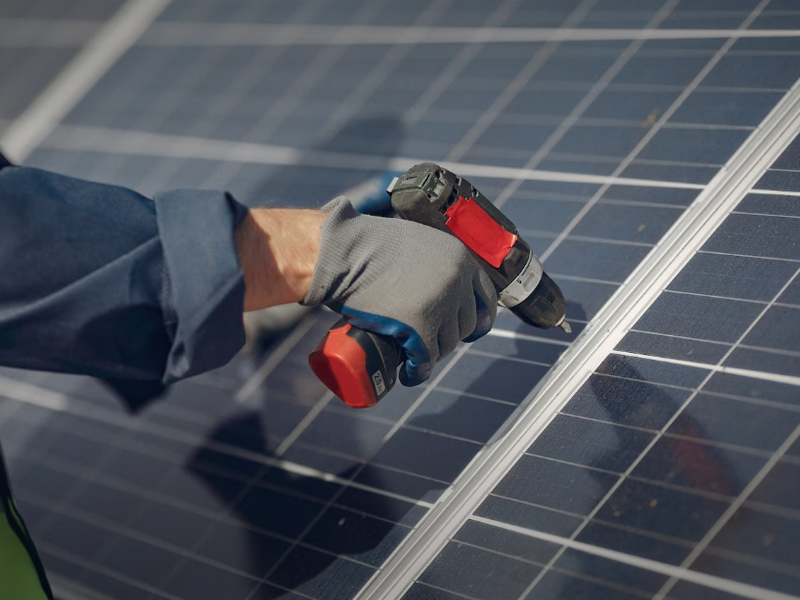

The power line project was originally planned to start construction in early February and be connected to the grid for power generation by the end of June. However, recently, due to the impact of the novel coronavirus pneumonia, the project’s commencement was postponed for nearly a month. In fact, construction did not start until early March, and the construction period was extremely tight. Under the current epidemic situation, Black Crystal Optoelectronic Technology Co., Ltd. not only strictly implements epidemic prevention and control measures, ensuring the project is completed on schedule, but also guarantees the safety of employees returning to work. Black Crystal Optoelectronics actively communicated and negotiated with the factory to formulate a meticulous plan. Both sides worked closely together, adopted measures such as shift work and night processing and construction, optimized the work process, accelerated the progress of the photovoltaic project construction, and ensured the normal production and operation of the factory. As of April 9, 2020, the reinforcement project of the factory area has been successfully completed. Currently, the project is in the next stage of work to ensure that it can be connected to the grid and put into use in June this year.